5-Five Epoxy Resin

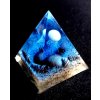

Transparent epoxy resin for pouring up to 5 cm thick. The product is specifically designed for the creation of wood and resin tables and countertops, as well as for potting in the creation of artistic products with a higher casting column such as resin pyramids and designer furniture, and for the creation of castings with fillers (stone, metal, cork and many others).

It is a high quality resin with UV protection and casting to a higher column.

This resin is suitable for pouring into silicone moulds from our range up to a thickness of approx. 5 cm.

The resin is supplied with hardener. The quantity purchased is the sum of the weight of components A and B.

Mixing ratio: 100 : 55 (by weight).

Producer: RESIN PRO ITALY

Clouding of the A component of resins (milky colour, white pieces, lumpiness, etc.) is a common phenomenon caused by storage at temperatures below 20 °C (in storage, during transport, etc.). If clouding is detected when casting component A, do not mix the resin with component B. First, place the sealed bottle with ingredient A in a warm water bath (50-70°C) for 20-30 minutes and the cloudiness will disappear. Let cool and then process.

The 5-five epoxy resin is a unique product that allows pouring up to 5 cm thick, is UV stable and resistant to mechanical damage. It is suitable for working at ambient temperatures up to 30 °C. It is an excellent choice if you want to create tables, boards, pyramids and other resin and wood products in the summer.

This resin is fully transparent and can be applied in layers of about 5 cm. In the case of higher castings, we recommend casting it in layers, after partial or complete hardening of the bottom layer. It can be well coloured and pigmented. Cures in approx. 48 hours, is easy to work and polish. It has excellent mechanical properties, high strength and cohesion. The cured resin surface resists scratching and other non-critical damage. Due to its low viscosity it removes air bubbles well during the curing process.

Be the first who will post an article to this item!