How to sand and polish epoxy resin products

Are you preparing to sand and polish your resin product?

Before you start the final finishing of the casting, always let it fully cure. Although we remove the casting from the mold in a hardened state, it does not mean that all chemical processes have completed. The casting continues to cure and harden. The casting is suitable for sanding after approximately 10-14 days. Sanding an uncured casting will only lead to excessive clogging of the sandpaper, and you will never achieve a perfect shine.

##MEDAILONEK_EN_001##

What will you need?

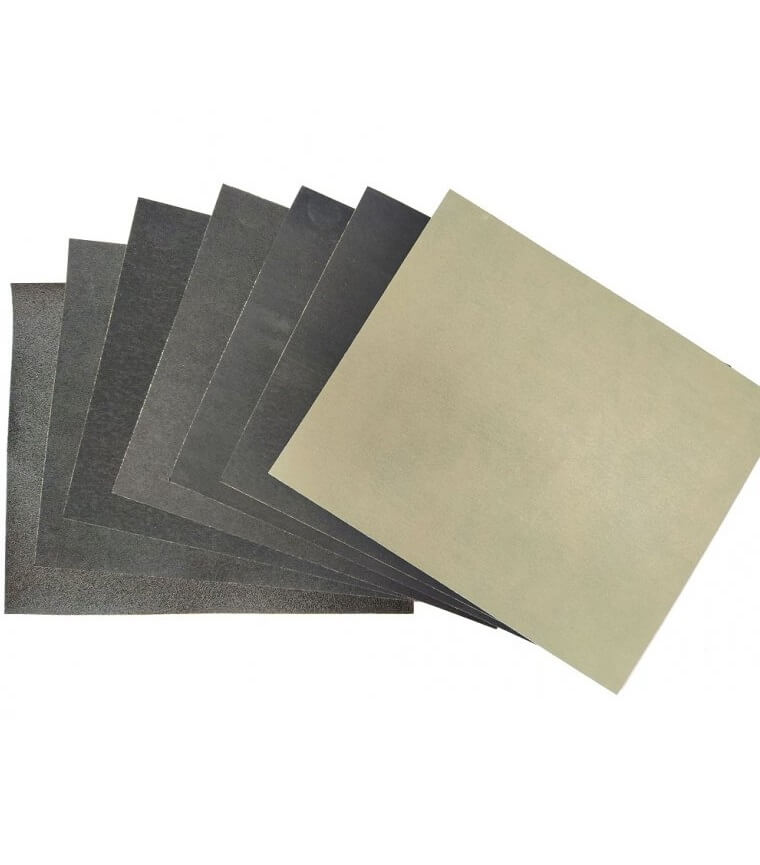

For sanding an epoxy resin casting, you will need sandpapers up to grit 3000, i.e., all grits from coarse 220 to the finest 3000. The coarsest grit used depends on how much material you need to remove. It is often sufficient to start with a finer grit 600 and gradually work up to 3,000.

You will also need polishing paste and a microfiber cloth.

Sanding and polishing procedure

Sand with each grit gently without applying pressure on the material, using circular motions up to grit 3000. Never skip grits!

It is hard to estimate how much time you should spend on each grit. Observe if the sanded surface is uniform and corresponds to the grit used and if there are no visible scratches from the previous paper. It might take 5 minutes or even 15. It depends on the technique and the state of the sanded casting.

However, if you want to achieve a matte surface, it is not necessary to sand up to grit 3000.

After perfect sanding up to grit 3,000, finish polishing the casting with a microfiber cloth and nano polishing paste. The same rules apply for polishing with nano paste as with sandpaper, i.e., using circular motions without applying pressure on the polished casting.

A few tips for sanding and polishing resin

- During sanding, whether manual or machine, frequently wipe the casting surface and sandpaper with a microfiber cloth.

- For better results, we recommend using water while sanding.

- Don’t forget to protect your respiratory system and eyes!

- Sanding with water also helps in reducing the release of sanding dust into the environment. Resin dust is very fine and gets everywhere.

Sanding and polishing resin is a challenging technique. You might not achieve a perfect shine on your first sanded casting, and it will be a time-consuming process. However, do not give up. Once you get the hang of sanding, you will find your rhythm and know when to switch to finer sandpaper, achieving excellent results!

VIDEO: Sanding and polishing resin

##PRODUCT-WIDGETS-33832##