How to work with NatuResin mineral resin

Working with NatuResin is fun and simple! Just follow a few basic rules and you can look forward to beautiful creations. In this article, we’ll explain how to best prepare your workspace, how to color the creative medium, and when you can enjoy your finished product.

Let’s get started!

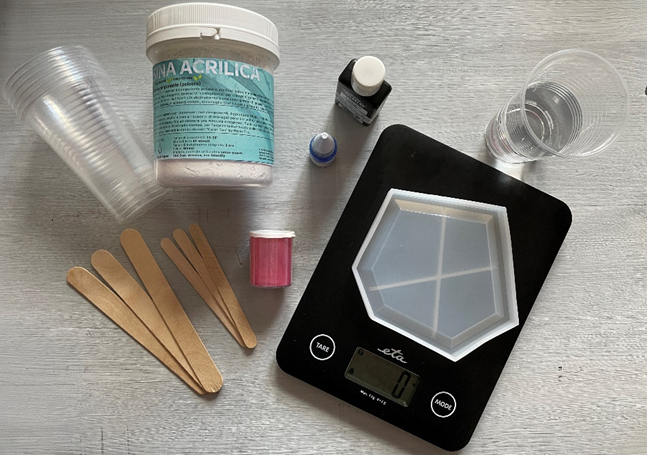

##MEDAILONEK_EN_001##

Preparing the Workspace and Tools

Before mixing the components, prepare everything you will need. This way, you can focus on the casting itself without wasting precious time looking for colors or molds after mixing. We have a few minutes to process the mixed medium, but time flies quickly when searching for things if we are not prepared.

We need:

- a work surface mat, such as baking paper or shrink wrap

- a digital scale

- cups

- spatulas

- colors designed for coloring NatuResin mineral resin

- silicone molds

- water

- mineral resin NatuResin

Use a spirit level to ensure your work surface is level. It is better to be prepared in advance because leveling can be a complicated task after casting into molds. Although mineral resin does not adhere to the work surface as thoroughly as epoxy resin, we still recommend covering the work surface with baking paper to avoid any potential cleanup. Prepare silicone molds not only for the products you want to make but also a small additional mold for any leftovers. Don’t have an extra mold? No worries! If you have leftover mixed medium, pour it in a thin layer on baking paper. After curing, you can break it and use it to create a mosaic or terrazzo effect.

Next, prepare the colors you want to use. The base color of the uncolored medium is white, though not completely bright white. It might seem like you can color the medium with any available color, but that's not the case. Mineral resin is inherently opaque and does not take color as easily as epoxy resin. Coloring is only possible with highly pigmented colors that are proven for this medium and available in our range. The result will be pleasant, pastel shades.

Prepare cups and spatulas and pour water into any container. Ideally, the container for water should have a spout for precise pouring in grams.

All set? Let’s go!

Place the cup in the center of the scale and zero the scale. The cup should be large enough to comfortably mix both components.

NatuResin is mixed at a ratio of 100:27, meaning 100 grams of powder and 27 grams of water. Failing to maintain this ratio can result in decreased strength, slower curing, and reduced product lifespan.

The ideal environment for mixing is around 20 °C for the environment, the medium, and the water. The environment should also not be exposed to direct sunlight or excessive humidity (approximately above 40% relative humidity).

The mixing cup must be dry and clean. Weigh the water and the dry component separately.

Always add the dry component to the water, not the other way around. This avoids unmixed powder in the crevices of the mixing container. While stirring continuously, gradually add the dry component until both components are fully combined and the mixture is liquid and free of lumps.

After mixing both components, you can add color from the COLORFUN range. We recommend adding color up to approximately 2% of the total weight of the mixed casting medium.

Colors from the Dye Solution range, alcohol inks, and metallic powders in our range also work well for coloring. However, remember that while metallic powder colors retain their color after mixing with NatuResin, they do not retain their metallic sheen.

How much time do I have for processing?

The processing time is approximately 12 - 15 minutes. However, don’t delay casting; in larger mixed quantities and depending on the temperature of the medium and the surroundings, the medium may set faster.

What about bubbles? How do I get rid of them?

Lightly tap the filled mold from the sides or create vibrations on the work surface. This will help release air bubbles from the mixture, which occur during mixing.

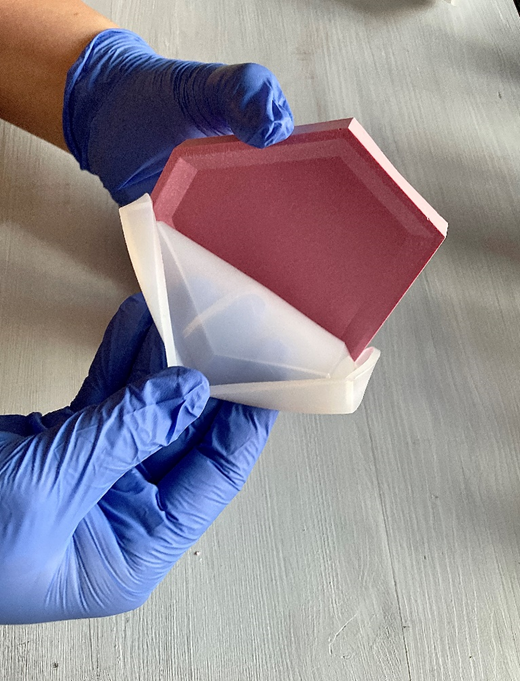

How long should I wait to remove the product from the mold?

You don’t have to wait long for the product; you can remove it from the mold within 40-60 minutes. The medium heats up due to the thermochemical reaction during curing and then starts to cool. When the casting is cool, you can carefully remove it from the mold. However, if you have a detailed mold or a mold with thin parts, we recommend letting NatuResin cure a bit longer before removing the product from the mold. This creative medium sets quickly enough to be removed from the mold, but the curing process continues for several hours, during which it will fully harden.

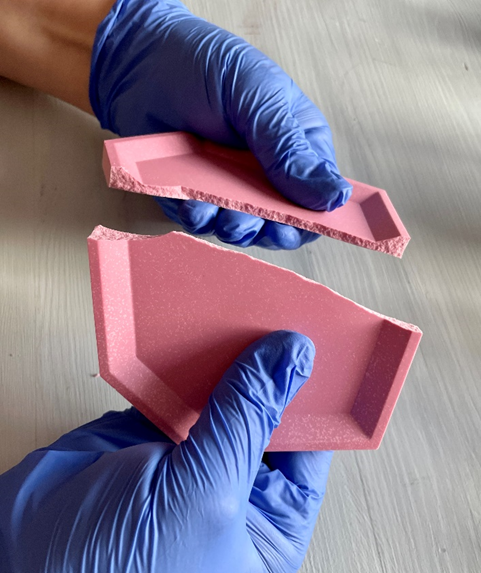

When to break the product if I want to cast the second half with epoxy resin?

We recommend breaking the product when you remove it from the mold, or shortly after curing. Doing it later would be very difficult as the medium will have fully hardened in a few hours and will be very hard to break.

Want to read about how to combine mineral and epoxy resins? We have an article on this topic. Click here to read it.

Tip: Not sure how much casting medium NatuResin you will need for your molds? Before casting, weigh how much water fits into the chosen mold. Multiply this weight by 1.5 to get the approximate weight of the dry component needed to create your original product.

##PRODUCT-WIDGETS-33664##